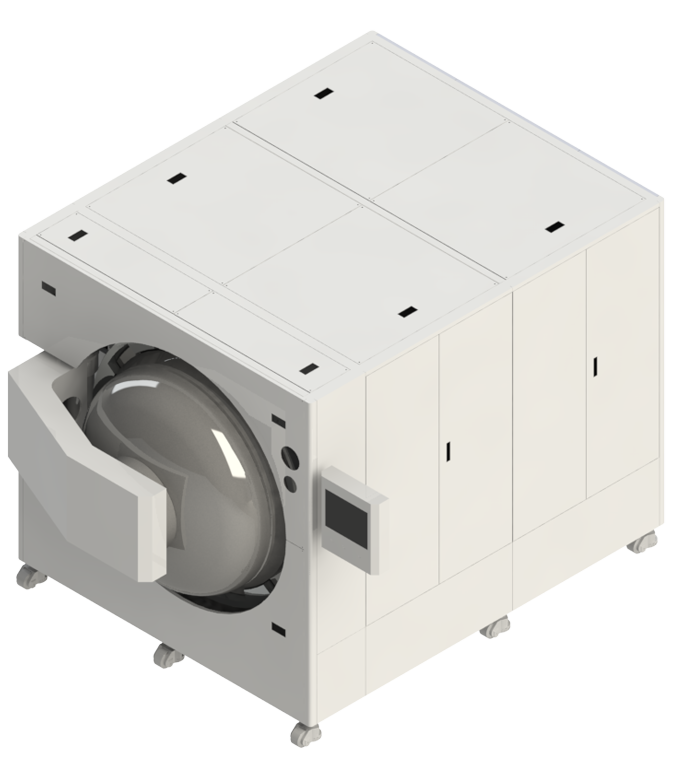

Pressure Curing Oven

Pressure Curing Oven for film bonding (FA series)

Product summary Information

Applied to lamination processes that require multiple film bonding, and improves performance through uniformity of layers by removing bubbles between film layers

Key Features

User Convenience | Uniform temperature control | ultimate safety

Application

Applied to the process of bonding films to touch panel or small LCD panels

Custom orders are also possible for conditions other than the standard specifications, so please consult with your sales representative.

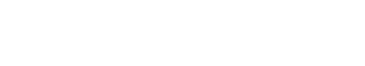

High Pressure Vessel

Designed for safety

– Designed based on ASME

– Domestic industrial safety and gas safety inspection carried out

– China SEL certification available

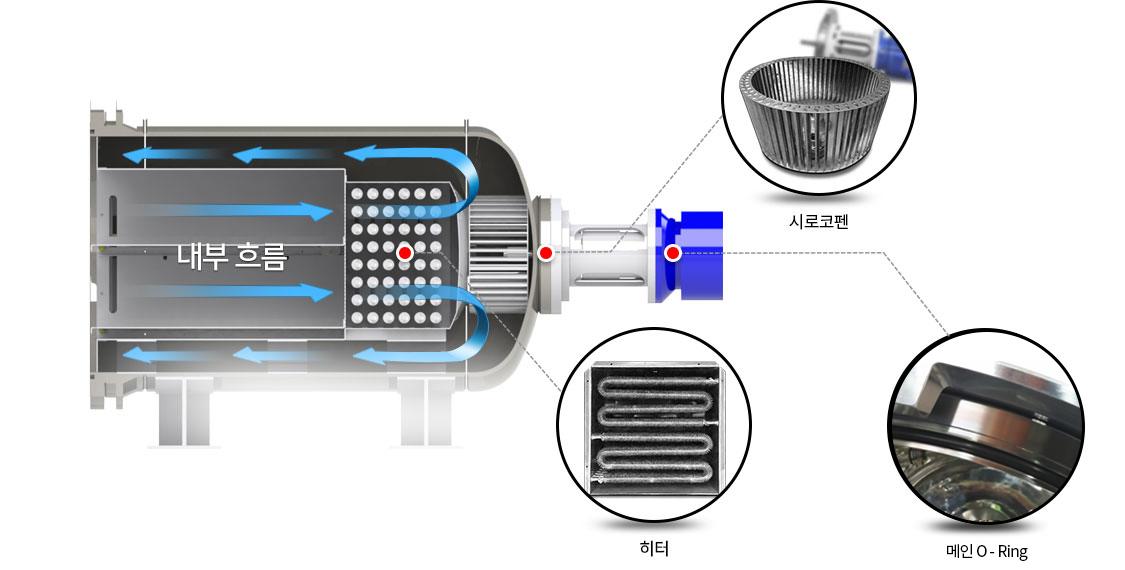

Fan System

Configuration specialized for cleanroom

– Dust-free system with integrated drive unit

– Equipped with a safety cover for the rotating part

* Material : Stainless steel

Heating System

Easy to attach and detach

– 100% guide to best air flow conditions

– Design to minimize loss

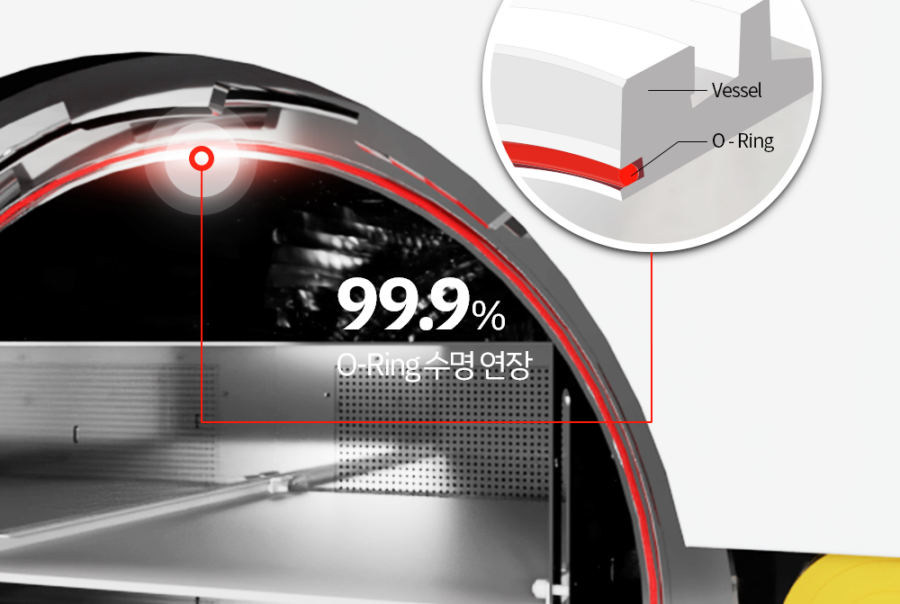

Main O-ring

O-ring Lifetime extension

Selecting the right material for the temperature

No Foreign matter

PCO – FA Series

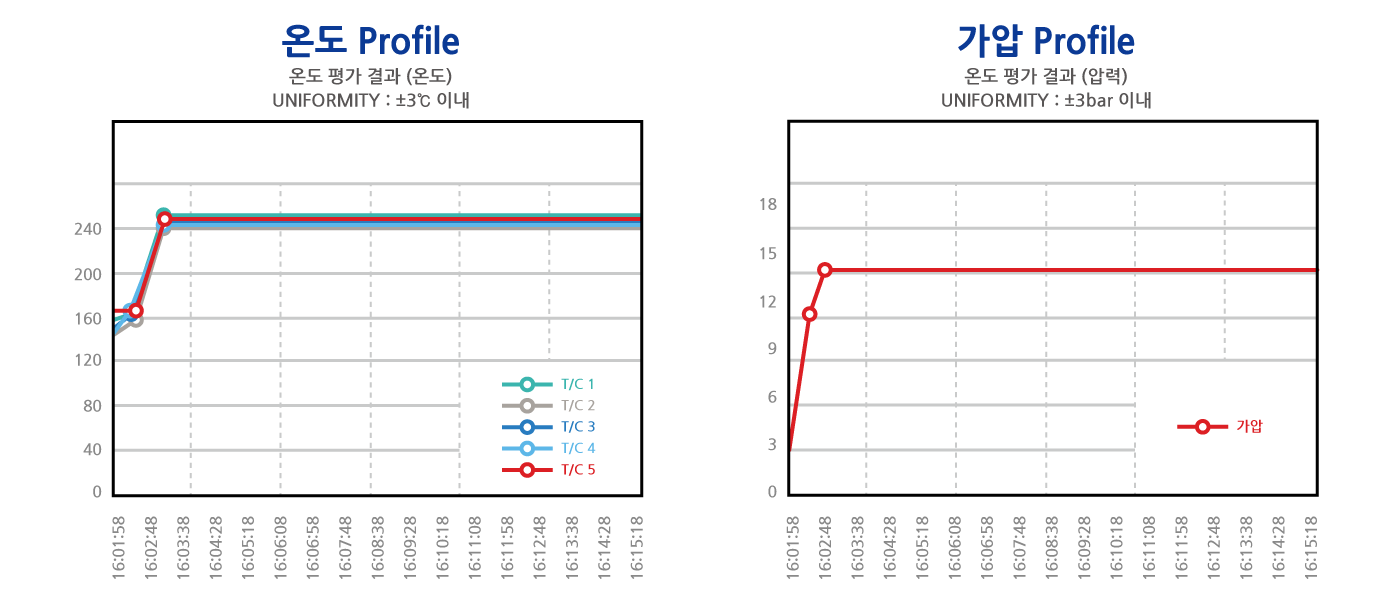

Temperature/Pressure TEST DATA

V.F.T(Valves, Fittings & Tubing)

Perfect pipe treatment with over 20 years of experience

Selection of materials that are not problematic for high pressure use, flow chart at a glance

Main control panel

Easy to operate

and High performance control panel

| Series | FA3 | FA5 | FA6 | FA9 | FA12 |

|---|---|---|---|---|---|

| Inside diameter (㎜) | 300 | 500 | 600 | 900 | 1,200 |

| Inside depth (㎜) | 300 / 500 | 500 / 1,000 | 1,000 / 1,500 | 1,500 / 2,000 | |

| Pressure (bar) | 8 / 20 | ||||

| Temperature (℃) | 80 / 100 | ||||

| Material | SUS304 / SMCM439 | ||||

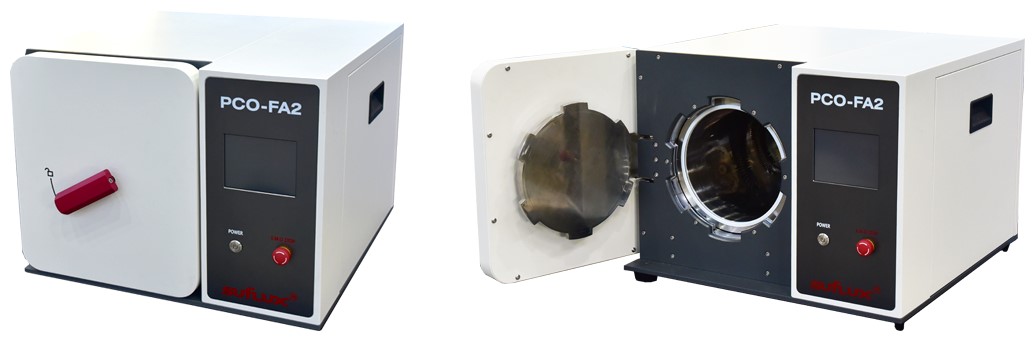

| Series | Image | Details | ||

|---|---|---|---|---|

| FA3 |

|

Inside depth (㎜) | 300 | 500 |

| Equipment Size (㎜) | 1,529.5 x 885 x 1,450 (WxDxH) | 1,568 x 1,362 x 2,305 (WxDxH) | ||

| Equipment Weight (kg) | 800 | 900 | ||

| FA5 |

|

Inside depth (㎜) | 500 | 1,000 |

| Equipment Size (㎜) | 1,672 x 2,471.5 x 2,000 (WxDxH) | 1,672 x 2,471.5 x 2,600 (WxDxH) | ||

| Equipment Weight (kg) | 1,000 | 1,300 | ||

| FA6 |

|

Inside depth (㎜) | 500 | 1,000 |

| Equipment Size (㎜) | 1,690 x 1,400 x 2,100 (WxDxH) | 1,690 x 1,400 x 2,600 (WxDxH) | ||

| Equipment Weight (kg) | 1,500 | 1,800 | ||

| FA9 |

|

Inside depth (㎜) | 1,000 | 1,500 |

| Equipment Size (㎜) | 1,915 x 1,580 x 2,950 (WxDxH) | 1,915 x 1,580 x 3,230 (WxDxH) | ||

| Equipment Weight (kg) | 2,500 | 3,000 | ||

| FA12 |

|

Inside depth (㎜) | 1,500 | 2,000 |

| Equipment Size (㎜) | 2,125 x 2,080 x 3,020 (WxDxH) | 2,125 x 2,080 x 3,520 (WxDxH) | ||

| Equipment Weight (kg) | 4,000 | 5,000 | ||

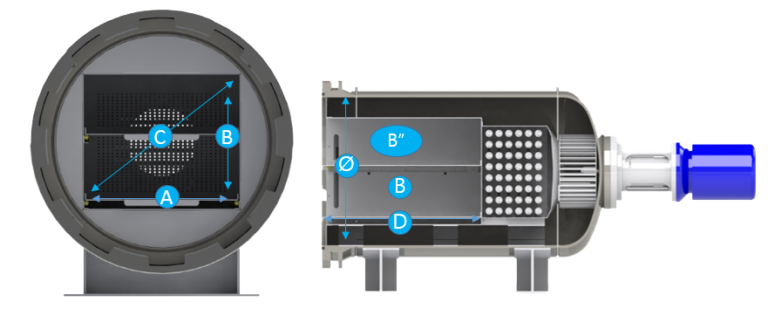

How to select Order-made Type

| Type | Inside diameter | Inside depth | Pressure | Temperature (℃) |

|---|---|---|---|---|

| A / B / B" (select) | Ø (calculate) | C (select) | Maximum Value to use (bar) | Maximum Value to use (℃) |

Caution

- Select the width of the first tray carriage (A selection criteria)

- Select the 2nd tray/carriage height and number of stages (B/B” selection criteria)

- When the above two A and B are selected, the way to find the inside diameter (Ø) is to find C since you know A and B, which are A(base), B(height) and C(hypotenuse)

- Square of hypotenuse(C) = Square of base(A) + Square of height(B)

- Hypotenuse(C)mm + 50mm = Inside diameter(Ø)

| Series | Working Vessel Dia (㎜) |

Working Temp. (℃) |

Working Pressure (kg/cm2) |

Temp. UNIFORMITY | Pressure UNIFORMUTY | Dimension (WxDxH) |

|---|---|---|---|---|---|---|

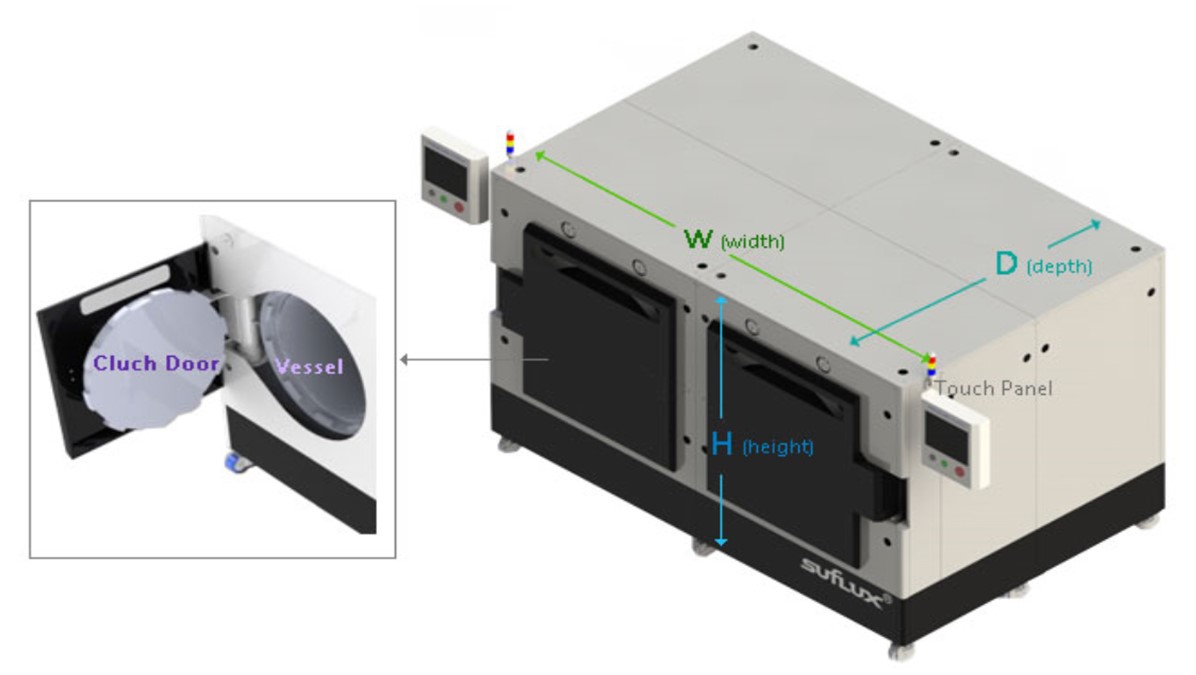

| PCO - FA | Ø 800 X 400 [2chamber] |

~ 80 | ~ 20 | Within ±3 ℃ | Within ±3 bar | 2,910 X 1,912 X 1,854 |

| Series | Inside diameter (㎜) | Inside depth (㎜) | Pressure (bar) | Temperature (℃) | Material |

|---|---|---|---|---|---|

| ISA-MP87 | 200 | 240 | 7 | 80 | SUS304 |

| ISA-MP2020 | 200 | 240 | 20 | 200 | SUS304 |