High Pressure Reactor

Special Reactors

Product summary Information

High-pressure reactors designed for specific purposes, classified as hydrogenation reactors, self-propagating combustion reactors, homogeneous parallel reactors, and continuous process reactors.

Key Features

Perfect Piping System | User Convenience | High Safety Standards

Application

Each reactor has distinct purposes and applications and can be utilized across various industries, including environmental, food, chemical, machinery, metal, electrical and electronics, and chemical industries.

Custom orders are also possible for conditions other than the standard specifications, so please consult with your sales representative.

- Hydrogenation Reactor

- Self-Propagating Combustion Reactor

- Homogeneous Parallel Reactor

- Continuous Process Reactor

- Download

Reaction system for hydride

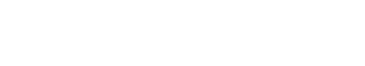

Hydrogenation Reactors

Reactors designed for continuous hydrogenation reactions on various samples

– Capable of handling a variety of hydrogenation reactions and continuous process treatments

– The reactor material is made of high-pressure-resistant stainless steel or carbon steel.

– The interior is lined with a dual-bonded, nickel-based material known for excellent chemical resistance.

– The vessel cover is fixed, allowing sample injection through piping.

– Various components can be installed to meet production goals and capacities.

– The nozzle typically includes inlets, outlets, safety valves, and thermocouples.

※ Optional features like a deep tube for gas injection during the process or cooling coils for rapid cooling are available.

Applications of Hydrogenation Reactions

Application Fields

Food Industry

– Production of edible oils from liquid fats

Chemical Industry

– Hydrocracking of hydrocarbons in the petroleum industry

– Conversion of bio-oils into alkanes (paraffins) or methanol

– Production of cyclohexane from benzene

– Production of toluidine from toluene

– Alcohol production from aldehydes and ketones

– Amine production from nitro compounds

Hydrogenation Reactions

Overview & Process

What is Hydrogenation Reaction?

– Hydrogenation is a chemical reaction that occurs between hydrogen molecules, atoms, or compounds in the presence of a catalyst. This includes hydrocracking and hydrogenolysis reactions, where hydrogen is added to double or triple bonds between atoms in a molecular structure, or bonds between atoms are broken with the addition of hydrogen. Examples include the reaction of hydrogen and nitrogen to produce ammonia, and the reaction of hydrogen and carbon monoxide, which produces methanol or hydrocarbons depending on the catalyst.

Most organic compounds with multiple bonds between atoms can react with hydrogen in the presence of a catalyst. Hydrogenation and hydrocracking are critical reactions in industry. Hydrogenation is used to produce edible oils from liquid fats, and many processes in the petroleum industry for making gasoline and petrochemical products are based on hydrocracking of hydrocarbons.

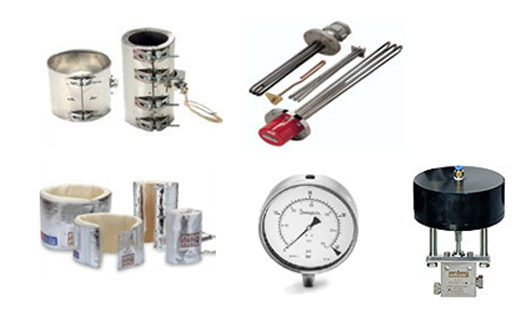

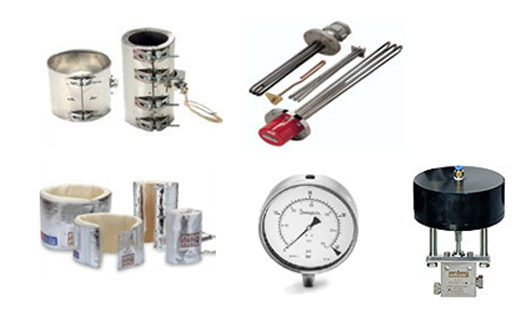

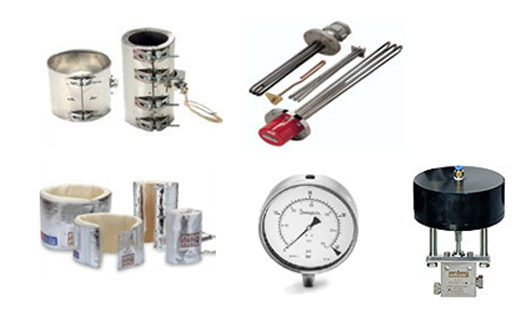

Options & Accessories

Options for convenience in experiments, accurate measurements, and specialized applications

Useful when added to the standard specifications

Special Reactors – Hydrogenation Reactor Specifications

| Model | Working Capacity | Working Temp. | Working Pressure | Magnedrive RPM |

|---|---|---|---|---|

| Hydrogenation Reactor | 500mL ~ 100L (Consultation) | -30 ~ 300℃ (Consultation) | Vacuum ~ 300bar (Consultation) | Low Speed ~ 500RPM (Consultation) |

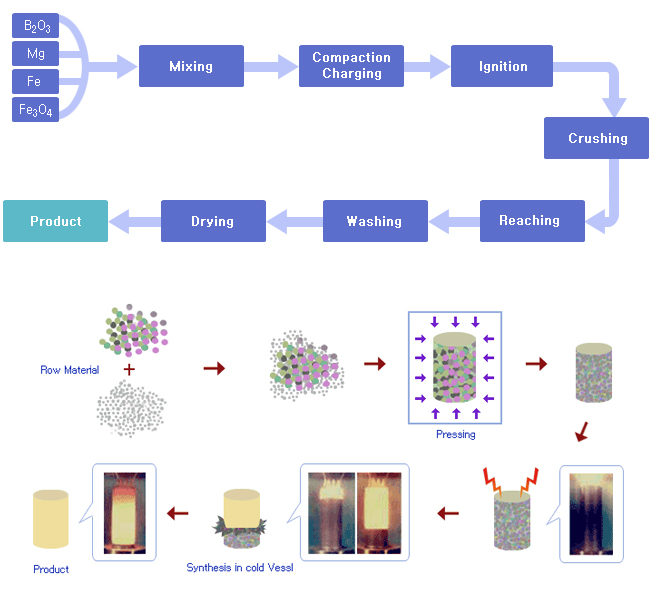

Reactor for Self-propagation

Self-Propagating Combustion Reactors

Reactors capable of performing self-propagating combustion synthesis, a material synthesis method that utilizes the exothermic reaction of reactants

– Equipped with a viewing window to observe the synthesis process externally

– Configured to connect an electric terminal for power supply to the interior of the reactor for synthesis

Applications of Self-Propagating Combustion Synthesis

Application Fields

Mechanical Industry : Abrasives, hard alloys

Metal Industry : Nitride ferroalloys, refractories in mixtures and samples

Electrical/Electronic Industry : MoSi₂, AIN, BN, etc

Chemical Industry : Catalytic decomposition, fumigants, pigment synthesis

Self-Propagating Combustion Reactors

Features & Advantages

– Enables high-purity nanomaterial production with high temperature and rapid reaction times

– Enables energy savings through self-generated reaction heat and allows for the production of high-melting-point metals and structural ceramic powders

– Reduces manufacturing costs through simple equipment and production processes

– Suitable for both small-batch, multi-product production and mass production

– Designed in compliance with ASME U1, U2 pressure vessel regulations

– Ensures accuracy and safety through dual pressure management

– Multi-stage safety features including safety valves and alarms

– Continuous equipment history tracking through alarm lists

Options & Accessories

Options for convenience in experiments, accurate measurements, and specialized applications

Useful when added to the standard specifications

Special Reactors – Self-Propagating Combustion Reactor Specifications

| Model | Working Capacity | Working Temp. | Working Pressure |

|---|---|---|---|

| Self-Propagating Combustion Reactor | 500mL ~ 100L (Consultation) | Over 100℃ (Consultation) | Vacuum ~ 200bar (Consultation) |

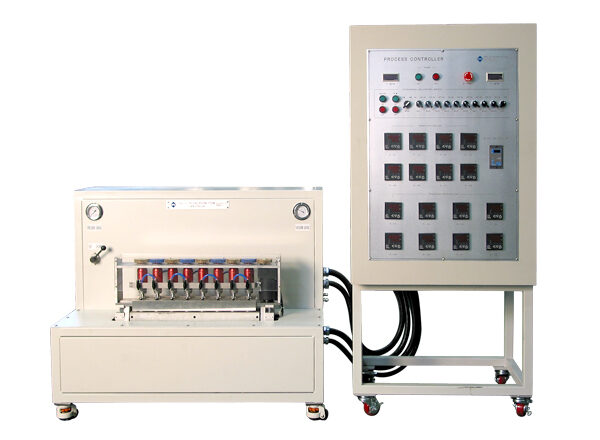

Reactor for Uniform Parallel

Homogeneous Parallel Reactors

Equipment that allows testing under uniform conditions

– Allows for various experiments by changing the quantities of raw materials, catalysts, and solvents across multiple identical reactors (8 sets) under the same conditions (temperature, pressure, rotation, etc.) to observe the effects on reactivity and reaction outcomes

Homogeneous Parallel Reactors

Features & Advantages

– Allows for configurable options based on each reaction stage

– Selective configuration to optimize reaction efficiency based on the process

– Enables accurate experiments with uniform conditions inside the reaction vessel

Options & Accessories

Options for convenience in experiments, accurate measurements, and specialized applications

Useful when added to the standard specifications

Special Reactors – Homogeneous Parallel Reactor Specifications

| Model | Working Capacity | Working Temp. | Working Pressure | Magnedrive RPM |

|---|---|---|---|---|

| Homogeneous Parallel Reactor | 300mL ~ 100L (Consultation) | -30 ~ 350℃ (Consultation) | Vacuum ~ 350bar (Consultation) | Low Speed ~ 100RPM (Consultation) |

Continuous Reactor System

Continuous Process Reactors

Reactors that facilitate stage-by-stage chemical reactions

– Conducts catalytic reactions for coal or petrochemical products in stages

– Configurable based on reactivity at each stage

– The system is sealed to prevent air contact, enhancing reaction efficiency.

Options & Accessories

Options for convenience in experiments, accurate measurements, and specialized applications

Useful when added to the standard specifications

Special Reactors – Continuous Process Reactor Specifications

| Model | Working Capacity | Working Temp. | Working Pressure | Material | Heating Unit |

|---|---|---|---|---|---|

| Continuous Process Reactor Main Reactor - 2SET |

0.5L (Inside Size : φ 65 ㎜ X 155 ㎜) | Over 350℃ (Consultation) | ~ 20kg/cm2 | HC276 | Ceramic Band Heater |

|

Continuous Process Reactor Pressure Filtering Reactor - 2SET |

0.5L (Inside Size : φ 65 ㎜ X 155 ㎜) | Over 350℃ (Consultation) | ~ 10kg/cm2 | SUS316 | Ceramic Band Heater |