Isostatic Press

Hot Isostatic Press (HIP)

Product summary Information

Equipment that can perform high-density sintering (metal, ceramic powder materials) and diffusion bonding of dissimilar metals by applying pressure at a temperature below the melting point of the material using gas as a transmission medium

Key Features

Quality Improvement | Excellent Stability | Applicable in various Industry

Application

Aerospace, energy, automobile, semiconductor, medical, etc.

Custom orders are also possible for conditions other than the standard specifications, so please consult with your sales representative.

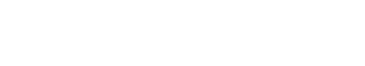

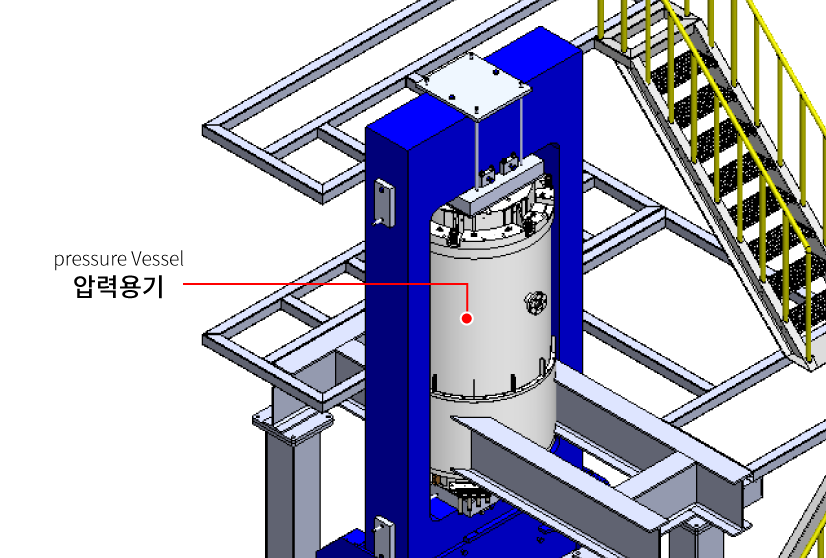

High Pressure Vessel

Optimization of pressure vessel design

– Designed according to U.S. ASME standards

– Conducting domestic industrial safety inspections with Korea Gas Safety Corporation

Safe Pressure Vessel design

Design applied to high temperature processes

Select Various Product

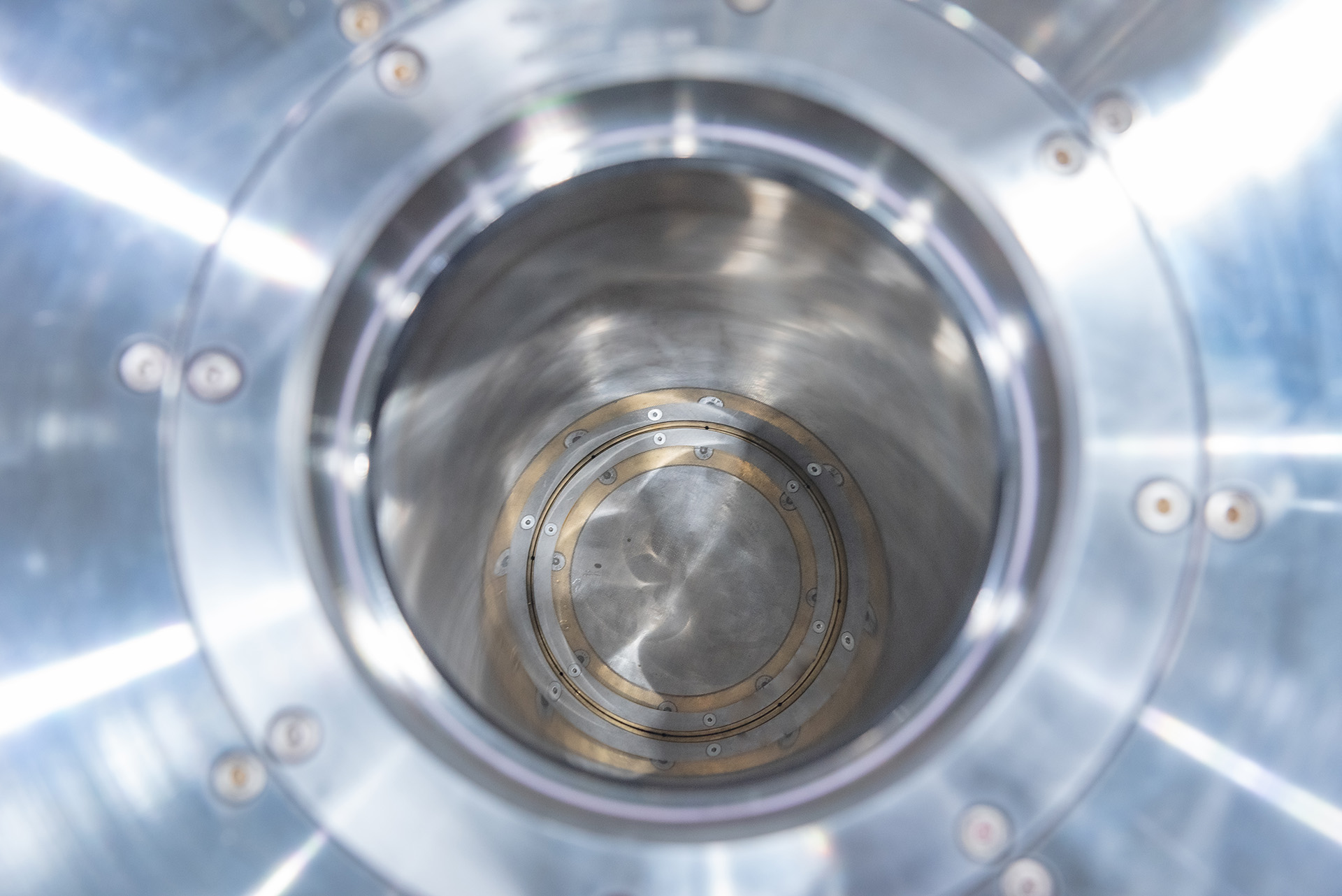

Classification by purpose of use

It is classified by materail type, temperature specifications, and production volume,

and are used in various fields such as aerospace, energy, automobiles, semiconductors, and medicine by utilizing high pressure gas

Selection Guide

How to choose Pressure vessel

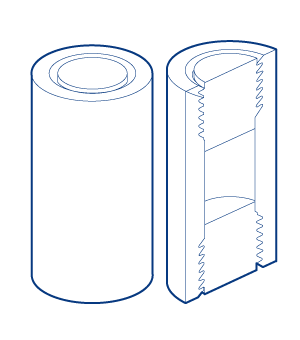

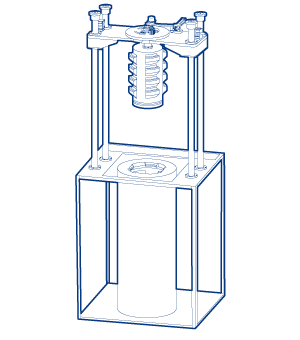

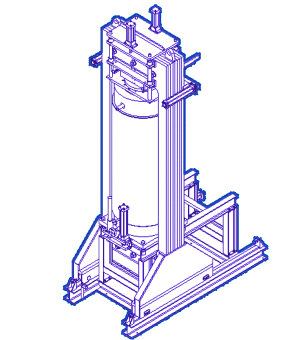

| Spiral seal type | Split spiral seal type | York sealed type | |

|---|---|---|---|

| Classification | Experimental | Experimental / Mass Product | Mass Product |

| Schematic |

|

|

|

| Summary | A container that can implement various experimental conditions with a perfectly sealed structure | A container suitable for use at high pressure and for producing large quantities of products on laboratory scale | A container suitable for mass production of prodcuts with an automatic opening and closing type that is suitable for large sizes |

| Details |

- Cover part automatic option available (product input/safety device added) - Hot heater and insulation structure - Easy to clean and maintain - Semi-automated process possible - Applicable to various sealed structures and materials |

- Movable Top Cover - Wire winding technology can be applied to the high pressure cylinder part - Improved durability , extended service life - Applicable to various products - Some mass production possible - Some sealing structures and materials can be applied |

- Yoke movable cover opening and closing - Double cover can be opened and closed (Heater and Insulation Repair Applications) - Wire winding technology can be applied to the high pressure cylinder part - Stable operation under high temperature & pressure - Automation process possible - Applicable to various sealed structures and materials |

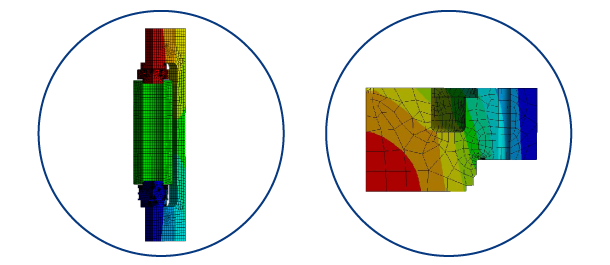

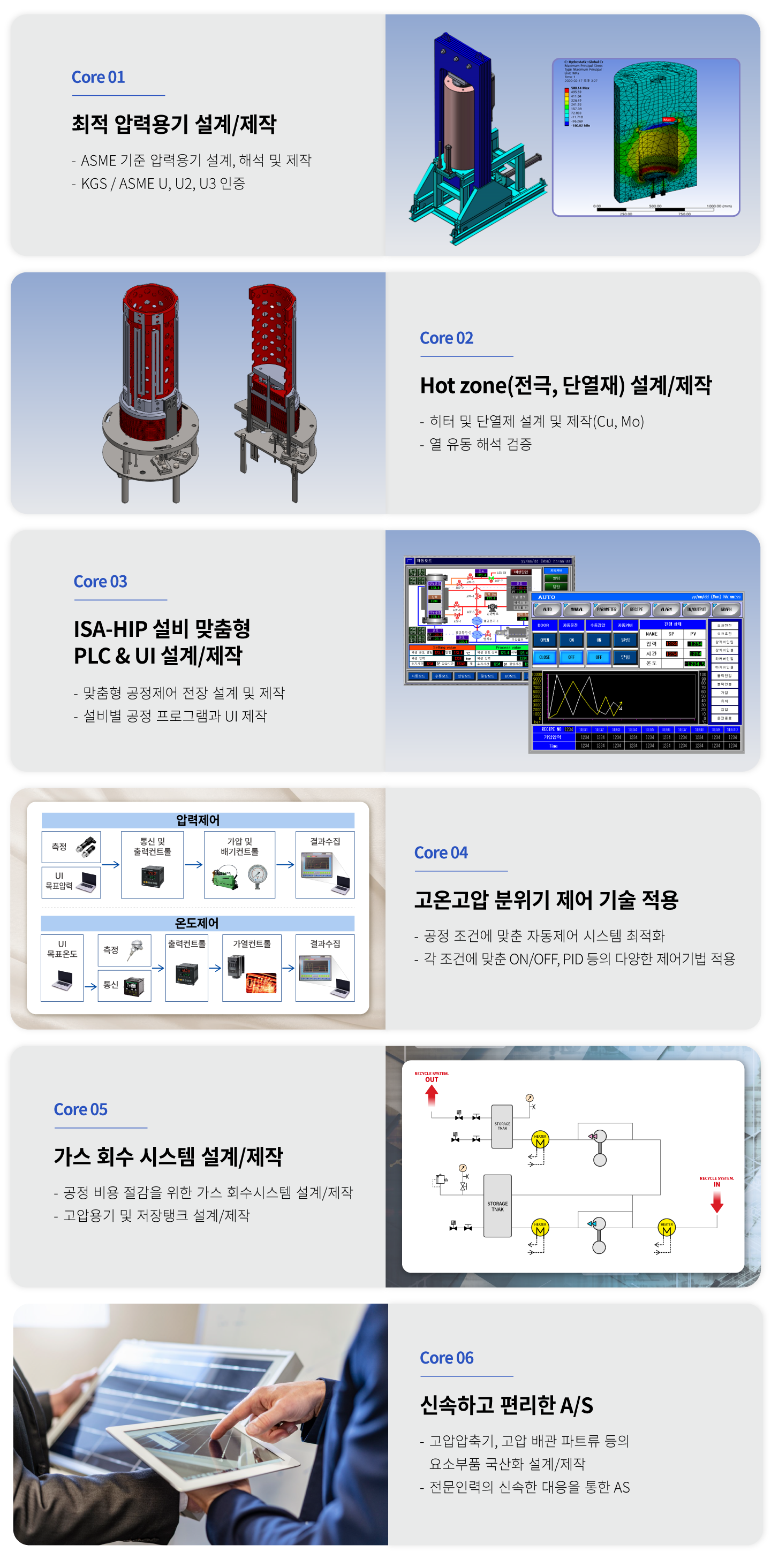

Core Technology

Core technology of hot isostatic sintering equipment

| Series | Hot zone dimensions | Temp. range | Pressure | Compressor |

|---|---|---|---|---|

| ISA-HIP 100 | Ф100 X 200 | ~ 1,500℃ | ~ 100MPa | Air booster / Hydraulic booster |

| ~ 2,000℃ | ~ 200MPa | |||

| ISA-HIP 200 | Ф200 X 300 | ~ 1,500℃ | ~ 100MPa | Hydraulic booster |

| ~ 2,000℃ | ~ 200MPa | |||

| ISA-HIP 300 | Ф300 X 600 | ~ 1,500℃ | ~ 100MPa | Hydraulic booster |

| ~ 2,000℃ | ~ 200MPa | |||

| ISA-HIP 600 | Ф600 X 1,200 | ~ 1,500℃ | ~ 100MPa | Hydraulic booster |

| ~ 2,000℃ | ~ 200MPa |

* For changes to the basic and optional specifications(gas recovery system, certification, etc.) please consult with your sales representative.

* The heater uses basic graphite material , but molybdenum material is also possible.

* Products other than those listed in the series can be manufactured according to customer requests.