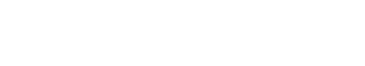

High Pressure Homogenizer

Nano Disperser (NLM100)

Product summary Information

It is convenient because it is possible to control the PCB using a high-pressure disperser, and the pressure and flow rate can be controlled by adjusting the speed of the motor. It has a compact design that is easy to move and transport.

Key Features

Compact design | User Convenience | High Safety Standards

Application

Used for various research purposes

Custom orders are also possible for conditions other than the standard specifications, so please consult with your sales representative.

Dispersion

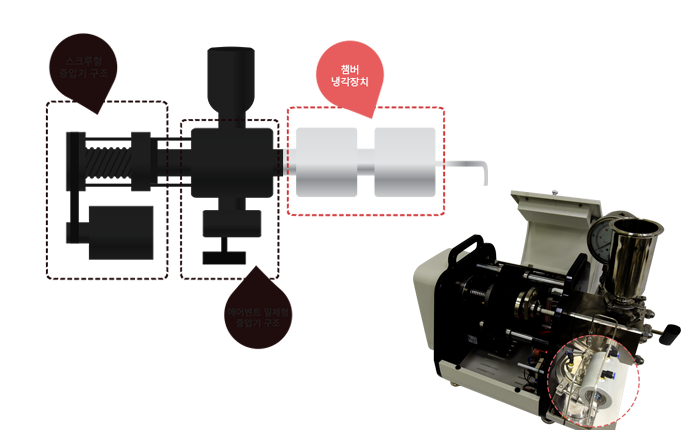

NLM100 compact disperser

– Excellent pressure performance and fast processing speed

– Preventing contamination and deterioration of raw materials and increasing miniaturization and usability

Detail

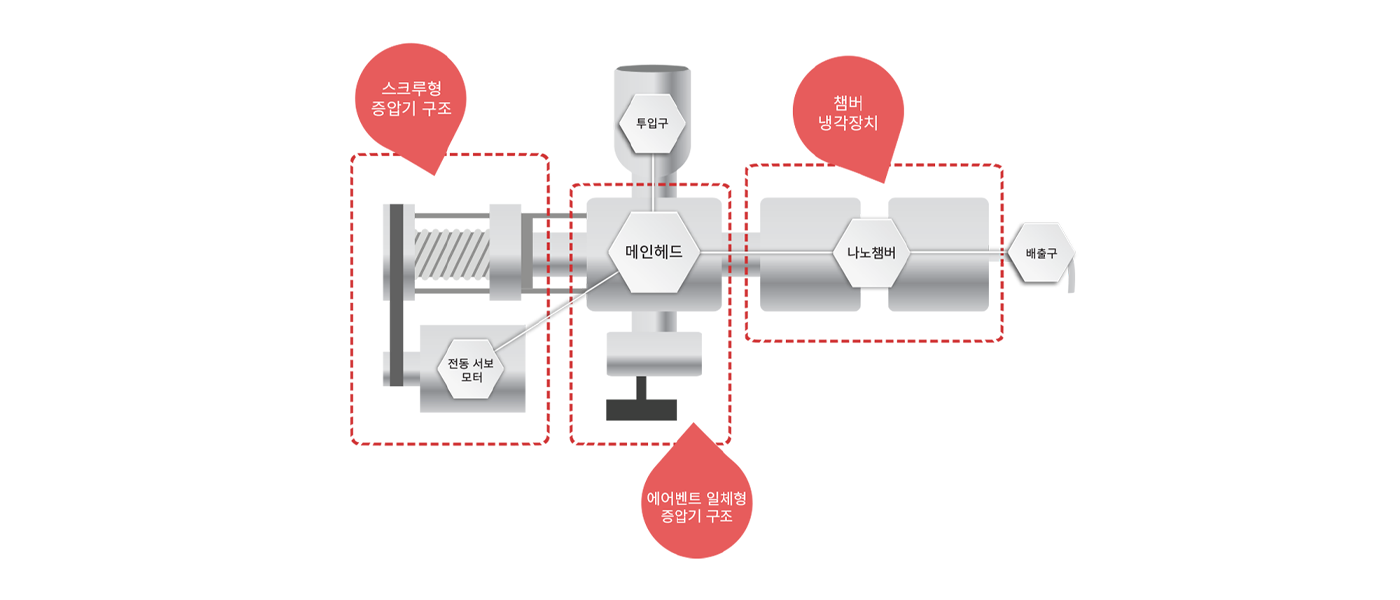

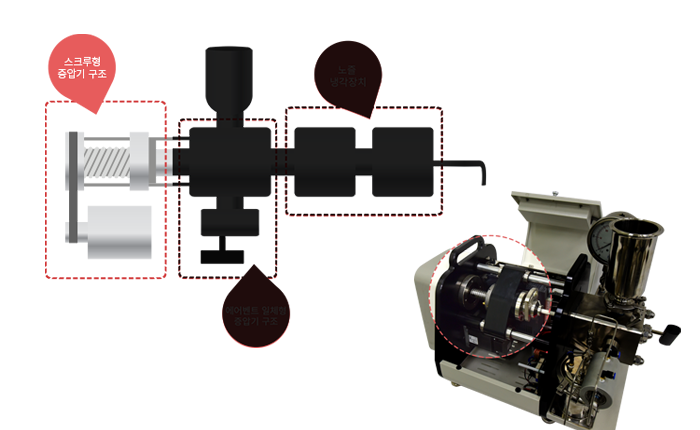

Specialized composition with long-standing know-how and technical skills

Increased pressure efficiency

– Development of a screw-type pressure booster capable of generating high pressure (2,000 bar)

Preventing Contamination of raw materials

– No risk of leakage of hydraulic oil, etc. due to adoption of electric drive

Increased usability

– Simplifies the structure and eliminates additional equipment by adopting electric drive

– Significantly reduced volume and weight, uses 220VAC power supply

Increased pressure efficiency

– Preventing injection of non-pressurized raw materials into the raw material line

Increase processing speed

– Easy to remove air inside the pressurized chamber

Increased usability

– Significantly reduced volume due to no additional plumbing installation

– Prevents raw material leakage by using high pressure (60,000psi) needle valve

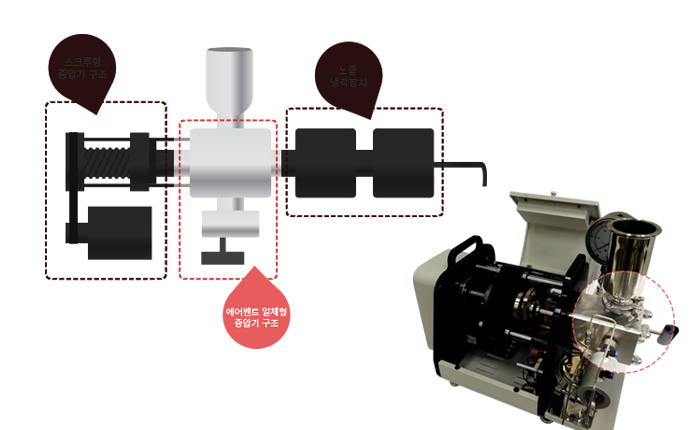

Preventing deterioration of raw materials

– Cools the nozzle to remove residual heat generated during the process

– Suitable for processes with heat-sensitive raw materials

Increased usability

– Capable of using refrigerants and coolers adapted to user environments

– Simple structure design allows easy assembly and disassembly

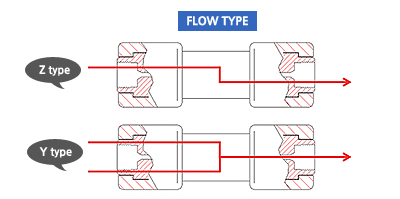

Interaction Chamber Type

Chamber Type

Z type : Recommended for dispersing and grinding powder in liquid (Suspension)

ex) CNT, Aluminum

Y type : Recommended for dispersing and grinding liquid in liquid (Emulsion)

ex) milk, water, oil

Emulsion State Comparison

Each type is used to create emulsified fuel (diesel + water) by utilizing high-pressure dispersers, agitators, and ultrasonic dispersers.

Video Ⅰ

Basic Operating Videos

NLM100 Basic Operation

Video Ⅱ

Cooling Tank Assembly Video

NLM100 Cooling Tank Assembly Process

Video Ⅲ

Chamber Assembly and Disassembly Video

NLM100 Chamber Assembly and Disassembly Process

NLM100 Series

| Series | NLM 100 |

|---|---|

| Operation pressure | Operating Pressure 1,500 bar |

| Flow Rate | Max. 100 mL/min |

| Pump System |

Motor Driven Type [220VAC, 1PH, 60㎐] |

| Weight | Approx. 45kg |

| Dimension (WxDxH) | 583 x 576 x 435 |

| Interaction Chamber Size | 75 ㎛ |

| Interaction Chamber Type | Z Type |