Isostatic Press

Cold Isostatic Press (CIP)

Product summary Information

Used to mold products of various sizes and desired shapes at room temperature that do not require in physical properties due to temperature

Key Features

Precise Process | User Convenience | High Safety Standards

Application

High-performance insulators and functional parts, high-strength composite materials, heating elements and special parts, ceramics, metals, carbon, powder molding, etc.

Custom orders are also possible for conditions other than the standard specifications, so please consult with your sales representative.

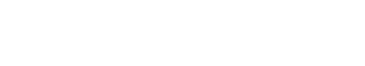

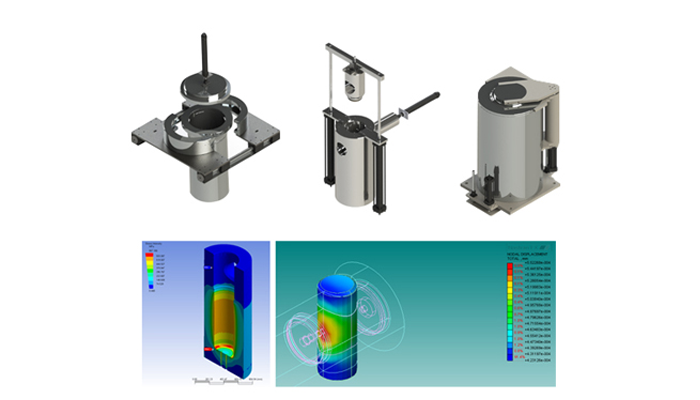

High Pressure Vessel

Safe Pressure Vessel design

– Designed according to U.S. ASME standards

– Domestic industrial safety and gas safety inspections carried out

Professional Engineering

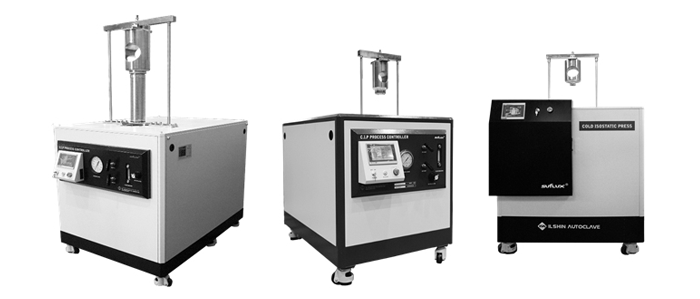

Experimental

– Compact design for laboratory space utilization

Professional Engineering

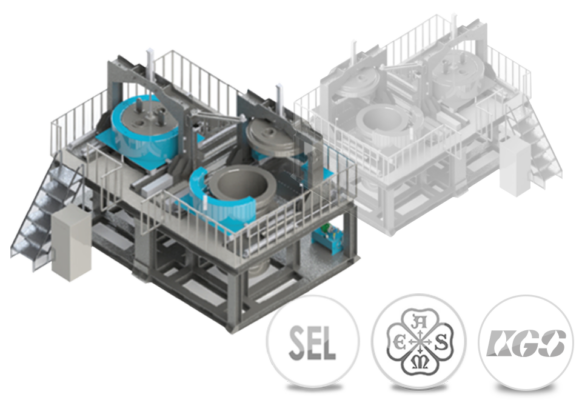

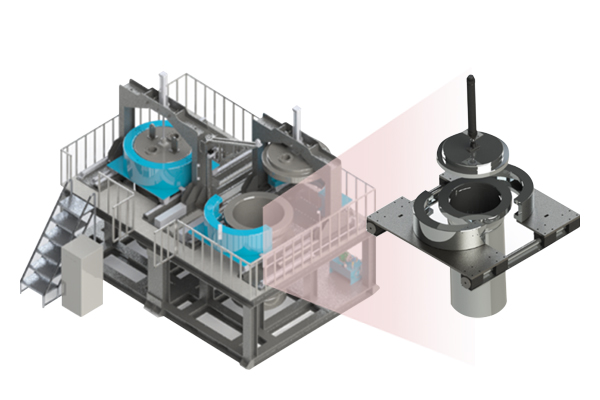

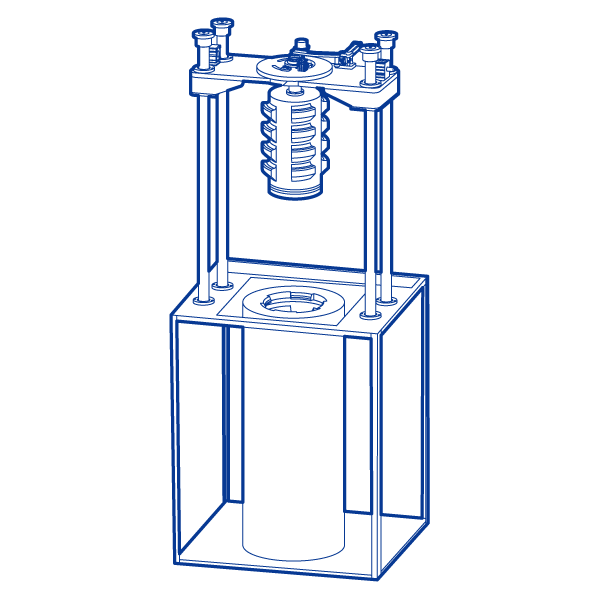

Mass Product CIP-C Series

Type of Using C-clamp for closing

– Movable Cover / Easy IN/OUT product

– Manufatured with a structure that is convenient to use at low pressure

– Structure that can be equipped with a heat jacket when temperature is required

– Can be used as an external pressure test device

– Easy to clean and maintain

– Automation process possible

– Can be equipped with a metering pump for low-volume , low-pressure applications

– Excellent energy efficiency

– O-ring Seal type

※ This equipment is suitable for producing large quantities of products at low pressure.

Professional Engineering

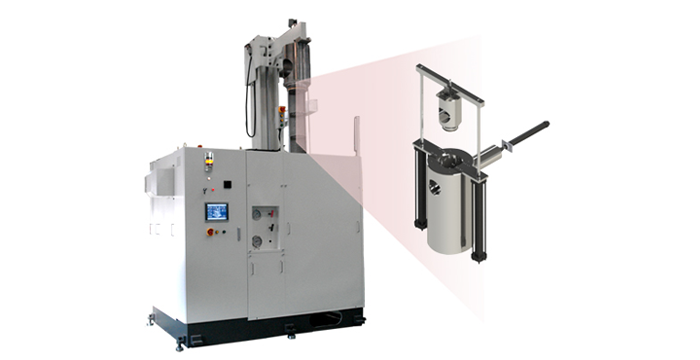

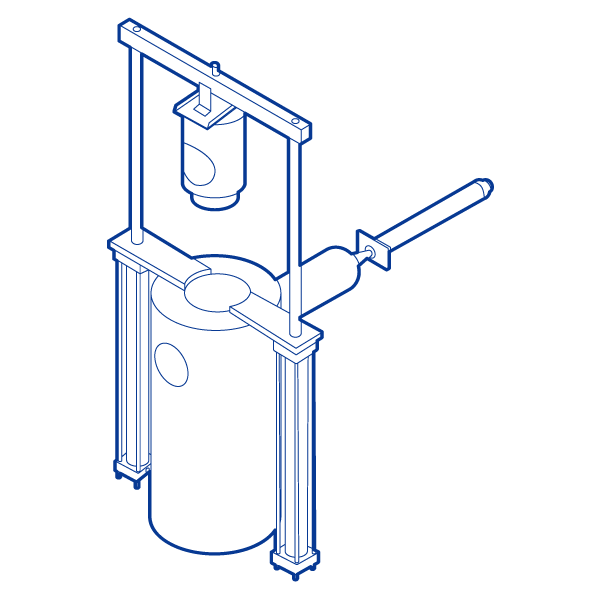

CIP-P Series for mass production

Method of combining the closing method with Pin and Cover

– Equipped with a basket for easy product loading/unloading

– Easy to maintain precise pressure difference at high pressure

– O-ring seal, U-packing

– Stable operation under high pressure

– Automation process possible

– Excellent energy efficiency

※ This equipment is suitable for producing large quantities of products at high pressure.

Professional Engineering

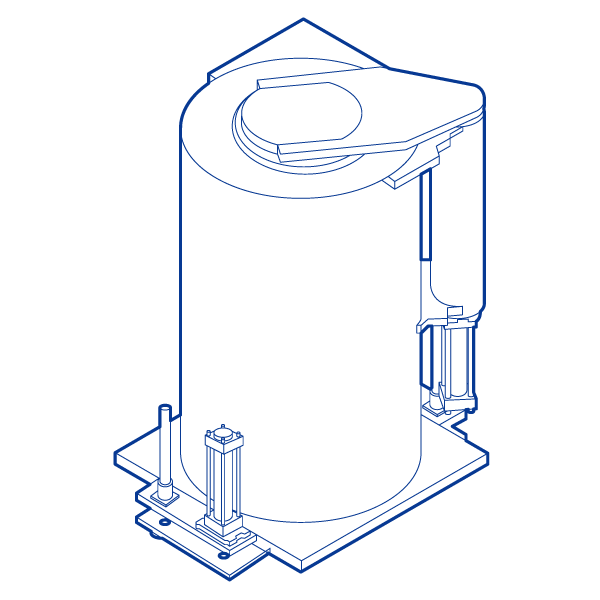

CIP-Y Series for mass production

Closing method using Yoke Frame

– Stable operation at ultra-high pressure

– Basket manufacturing for easy product loading//unloading

– Easy to maintain precise pressure difference at high pressure

– Automation process possible

– Excellent energy efficiency

– Incorporating O-ring Seal and U-packing wire winding technology

※ This equipment is suitable for producing large quantities of products at ultra-high pressure.

Video

Operating Principle Video

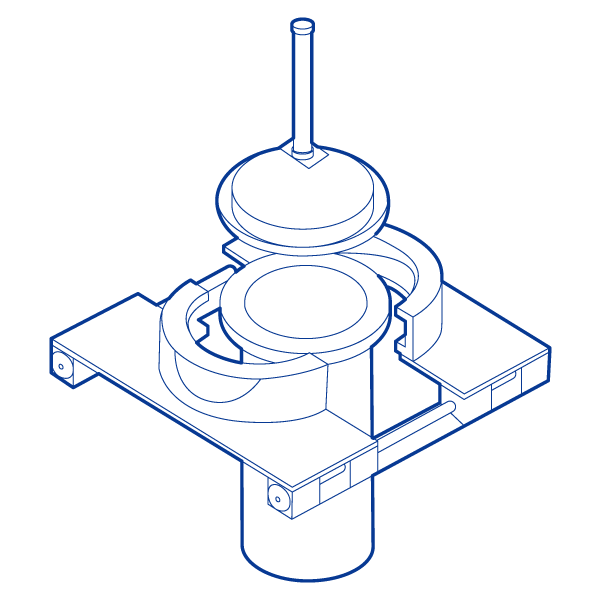

Principle of Isostatic Press

Selection Guide

How to choose Pressure vessel

| C-Clamp Type | Thread Closing Type | Pin Closing Type | Yoke Frame Type | |

|---|---|---|---|---|

| Applicable model | CIP / WIP | CIP / WIP | CIP / WIP / HPP | CIP / HPP |

| Schematic |

|

|

|

|

| Summary | This equipment is suitable for producing large quantities of products at low pressure. | This equipment is suitable for producing large quantities of products at high pressure. | This equipment is suitable for producing large quantities of products at high pressure. | This equipment is suitable for producing large quantities of products at ultra-high pressure. |

| Recommended Pressure | Below 1,000 bar | ~ 1,500 bar | ~ 4,000 bar | ~ 6,000 bar |

| Recommended Temperature | Room Temperature ~ 80℃ | Room Temperature ~ 130℃ | Room Temperature ~ 120℃ | ~ Room Temperature |

| Recommended Volume | Custom | 100L / Custom | 100L / Custom | 200L / Custom |

| Details |

- Movable Cover (Easy IN/OUT product) - Structure that can be equipped with a heat jacket when temperature is required - Can be used as an external pressure test device - Easy to clean and maintain - Automated process possible - Can be equipped with a metering pump for low-volume, low-pressure applications - Excellent energy efficiency - O-ring Seal Type |

- Equipped with a basket for easy product loading/unloading - O-ring Seal, U-packing Wire Winding Technology can be applied - Automation process possible - Excellent energy efficiency - Increased heating rate - Reduced temperature deviation - Improved durability , extended service life - Improve Productivity |

- Equipped with a basket for easy product loading/unloading - O-ring Seal, U-packing Wire Winding Technology can be applied - Automation process possible - Excellent energy efficiency |

- Equipped with a basket for easy product loading/unloading - Stable operation at ultra-high pressure - Automation process possible - Excellent energy efficiency - O-ring Seal, U-packing Wire Winding |

Main control panel

Easy to operate

and High performance control panel

Experimental

| Series | Volume (L) | Pressure (bar) | Pump | Closing Type | Temp. (℃) | Internal Diameter (Ф) |

|---|---|---|---|---|---|---|

| ISA - CIP 500 | 0.5 | ~ 6,000 | Air Drivedn | C-Clamp / Pin | RT | 50 ~ 100 |

| ISA - CIP 1000 | 1 | 70 ~ 100 | ||||

| ISA - CIP 2000 | 2 | 80 ~ 120 | ||||

| ISA - CIP 3000 | 3 | ~ 5,000 | 100 ~ 200 |

Mass Product

| Series | Volume (L) | Pressure (bar) | Pump | Closing Type | Temp. (℃) |

|---|---|---|---|---|---|

| CIP - C | ~ 2,000 | ~ 500 | Air Pump | C-Clamp | RT |

| CIP - P | ~ 100 | ~ 4,000 | Pin / Cover | ||

| CIP - Y | ~ 300 | ~ 6,000 | Hydraulic Pump | Yoke Frame | |

| CIP - Y | ~ 2,000 | ~ 3,000 |