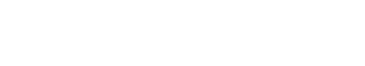

Pressure Vessel

CVB Series

Product summary Information

Pressure vessels in the CVB series are configured with a port for pressure checking and inlets/outlets for internal fluid flow.

Options for agitators, temperature sensors, and the number and size of ports can be added depending on the purpose of use.

Key Features

International standard ASME certification | Various Options | Strong corrosion resistance

Application

Mainly used for chemical experiments and research purposes, can be fastened with simple tools and minimal effort.

Custom orders are also possible for conditions other than the standard specifications, so please consult with your sales representative.

High Pressure Vessel

Safe pressure vessel design

– Designed according to U.S. ASME standards

– Domestic industrial safety and gas safety inspections carried out

Professional engineering

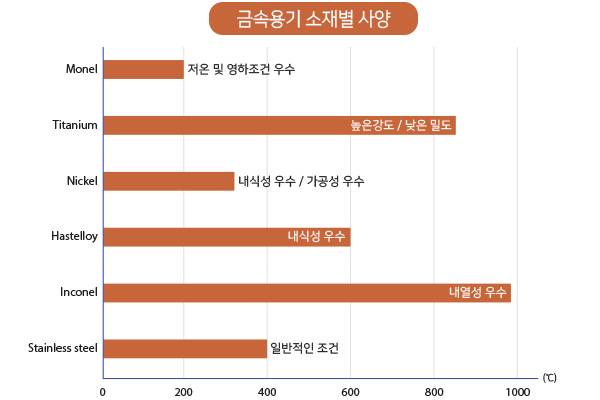

Excellent temperature/pressure/corrosion resistance in vessels

– Holding corrosion data tables

– Holding ASME materials tables

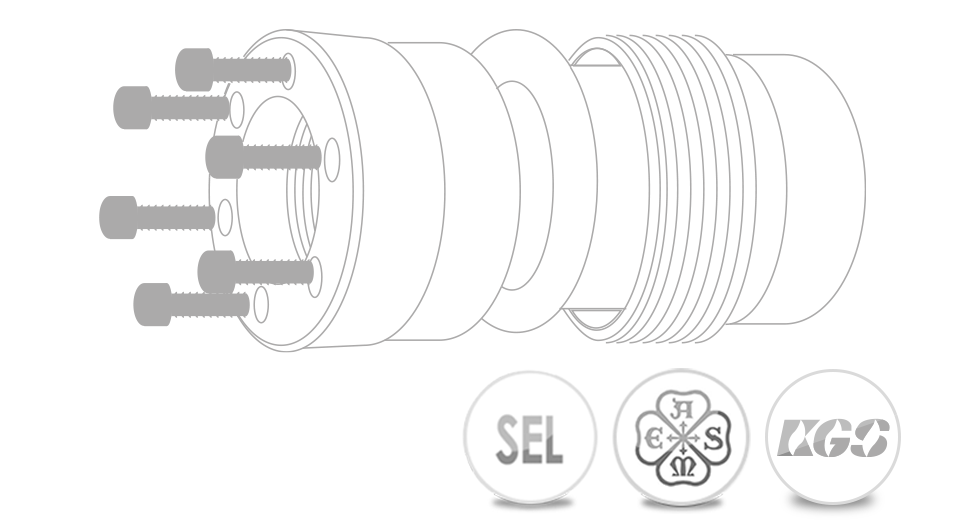

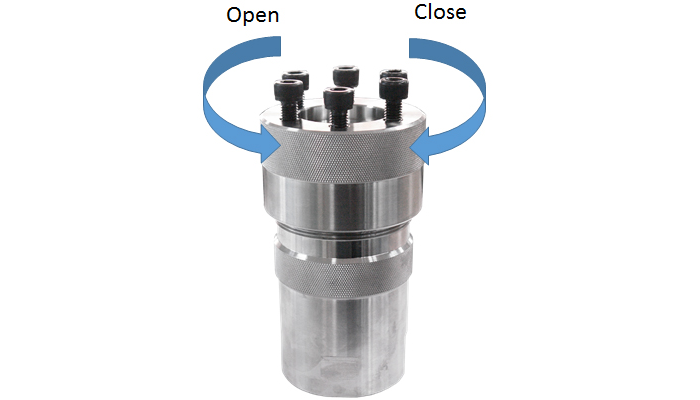

Easy closure type

Easy fastening method

Custom tool provision

Video

Pressure vessel fastening video

Fastening of CVB Series pressure vessels

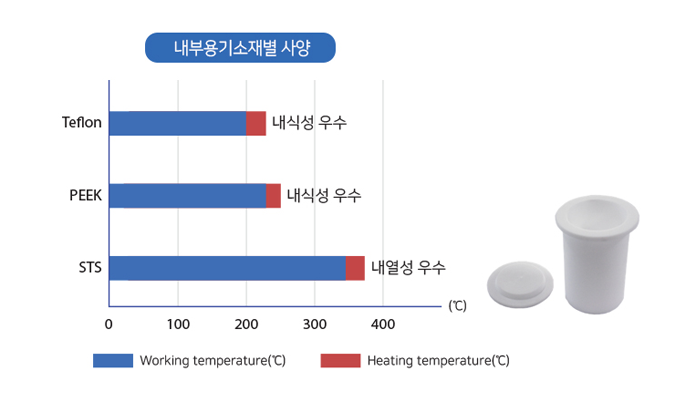

Chemical resistance container

Use of internal vessels without O-rings possible

– Teflon liner

– PEEK liner

– STS liner

CVB Series

| Series | CVB 5 | CVB 10 | CVB 20 | CVB 30 | CVB 50 | CVB 100 | CVB 200 |

|---|---|---|---|---|---|---|---|

| Volume (mL) | 5 | 10 | 20 | 30 | 50 | 100 | 200 |

| Max Temp. (℃) | 180 | ||||||

| Max Pressure (bar) | 100 | ||||||

| Material - Outside Vessel |

STS 316 | ||||||

| Material - Liner | Teflon | ||||||

| Seal of Liner | Surface Sealing | ||||||

| Closure Style | Cap Bolt Closure | ||||||

| Main Bolt | M40 X 2P | M45 X 3P | M52 X 3P | M70 X 4P | |||

| Vessel Dimensions (mm) - O.D | 55 | 60 | 65 | 83 | |||

| Vessel Dimensions (mm) - O.L | 100 | 110 | 128 | 155 | 132 | 195 | |

| Liner Dimensions (mm) - I.D | 15 | 20 | 26 | 45 | |||

| Liner Dimensions (mm) - I.L | 32 | 42 | 60 | 90 | 64 | 127 | |

How to select Order-made Type

| Type | Volume | Temperature | Pressure | Material |

|---|---|---|---|---|

| CVB | Required volume | Required temperature | Required pressure | Required material |

Caution

1. When using acidic or alkaline substances, it is necessary to decide on the right material.

2. Decide on options.

3. As the fastening method involves manual rotation, check size limits.

※ Since it is a custom production method, it is possible to freely select the container size and capacity according to the usage environment.