High Pressure Reactor

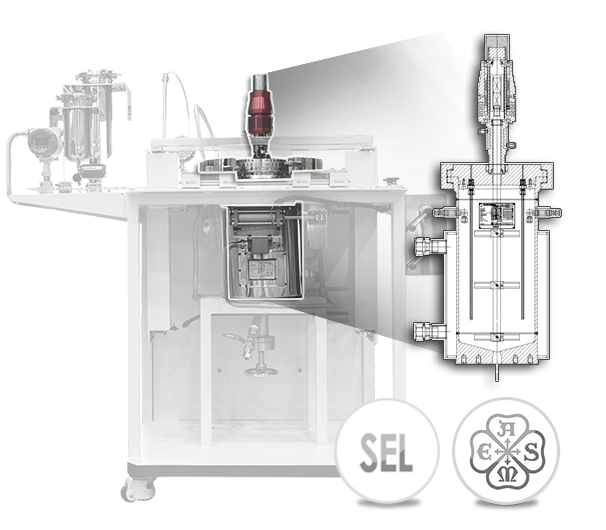

Multi-Purpose Reactor (Stand Type)

Product summary Information

Stand-type multi-purpose reactors with customizable specifications such as temperature, pressure, capacity, material, and RPM based on usage

Key Features

Easy Operation | Configuration of various options | High Safety Standards

Application

Suitable for various research purposes, including hydrothermal synthesis, rotation, pyrolysis, self-propagating combustion, and detonation reactions

Custom orders are also possible for conditions other than the standard specifications, so please consult with your sales representative.

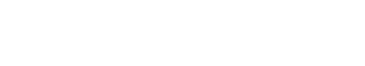

High Pressure Vessel

Designed for safety

– Designed based on ASME

– Domestic industrial safety and gas safety inspection carried out

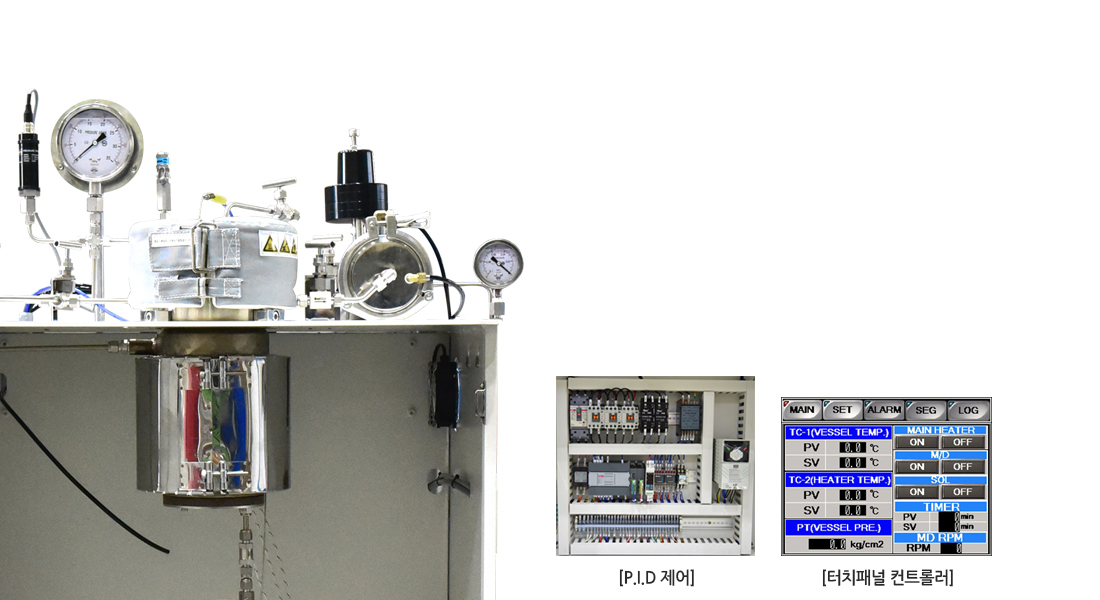

Heating System

Maintaining Constant Temperature Inside the Reactor

– Maintains constant internal temperature through heater and insulation

– Temperature control via PID control of the controller

Pressure Control System

Adaptable to Various Requirements

– Easy opening and closing of the pressure vessel

– Pressurization system configuration according to pressure conditions

– Continuous injection of various samples

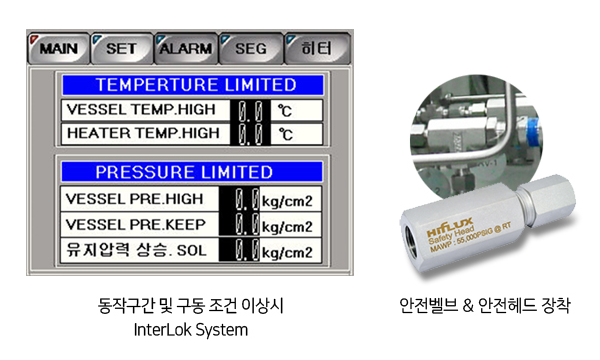

Safety

Multi-stage safety system

For enhanced safety, the equipment initially halts operation,

and if an issue persists, the safety valve activates for automatic discharge.

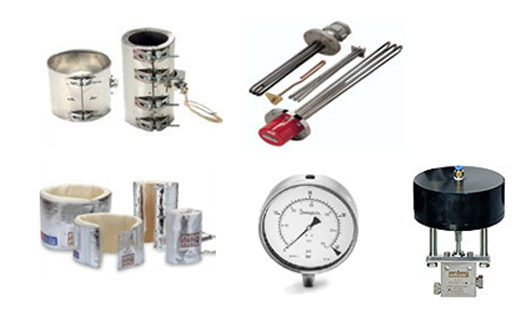

Options & Accessories

Options for convenience in experiments, accurate measurements, and specialized applications

Useful when added to the standard specifications

V.F.T(Valves, Fittings & Tubing)

Perfect pipe treatment with over 20 years of experience

Selection of materials that are not problematic for high pressure use, flow chart at a glance

Main control panel

Easy to operate

and High performance control panel

Multi-Purpose Reactor (Stand Type)

| Series | HR-S-500 | HR-S-1000 | HR-S-2000 | HR-S-5000 |

|---|---|---|---|---|

| Volume (mL) | 500 | 1,000 | 2,000 | 5,000 |

| Equipment Voltage | Consultation | |||

| Equipment Power | Consultation | |||

| Equipment Size (WxDxH) |

600 X 560 X 1,000 | 730 X 680 X 1,200 | 800 X 720 X 1,200 | 1000 X 760 X 1,700 |

| Equipment Weight (kg) | 45 | 65 | 75 | 90 |

| Design Condition | MAX. 200bar / MAX. 350℃ | |||

| Gasket | O-ring(Viton, Kalrez), Metal(STS304-316, Ni) | |||

| Electricity | Consultation | |||

| Magnedrive | Selectable | |||

| RPM | 320 RPM - Variable | |||

| Material | STS304, STS316, HC276, INC600, INC625, Ni, Ti | |||

| Liner | Teflon, Peek, Ti, Ni, STS304, STS316, HC276, INC600, INC625 | |||

| Impeller | Consultation | |||

| Options | Cooling coil, gas booster, hopper, condenser, pneumatic valve, regulator, heater (jacket type), TC (RTD, T, etc.), body cover (movable up, down, front and backward), sensor calibration | |||

Caution

- Size and weight information is for reference only.

- Please note that size and weight may change due to the custom manufacturing of the product.