SERVICE

Installation Cases

HOME > Support > Installation Cases

| Installed Products | RS10000-SMH (10L Stirrer Reactor) |

|---|---|

| Delivery Date | 2020 |

| Detailed Description | Summary 10L Stirrer Reactor for Chemical Treatment/Experiment Chemical Treatment: Butadien → Polybutadien latex |

| PROCESS – Max Pressure: 20kg/cm² – Max Temperature: 120℃ – Net Contents Volume: 10L |

|

| FEATURE – Explosion Proof Type (include Control Pannel) – Agitator: 6 paddles – Extra feeding available by Metering Pump(max capacity 400ml/min) – Ceramic band heater |

| Installed Products | 50L H2S-CO2 Corrosion Test Reactor |

|---|---|

| Delivery Date | 2020 |

| Detailed Description | Development Motivation and Equipment Introduction This device is designed to simulate high temperature (200°C) and high pressure (100bar) environments necessary for injecting H2S-CO2 gas and conducting corrosion performance tests on steel pipes, equipped with a heating system, pressurization system, and mixer as per the specifications of the Pohang institute of Metal industry advancement This equipment enables resistance testing for energy steel pipes in SOUR environments according to the detailed test criteria of the American Petroleum Institute Section 10. Inspection and NACE standard SOUR environment testing methods. |

| Differences between Existing and New Products This device is designed for process operation by quantitatively injecting gas in highly corrosive environments.1. Material improvement for use in corrosive environments – Manufactured from highly corrosion-resistant nickel steel (HC-276) instead of stainless steel (SUS304, 316), enabling process operations in corrosive conditions. 2. Application of MFC for quantitative gas injection – MFC is applied to control the ratio and flow rate of H2S-CO2 Gas according to process conditions. |

|

| Additional Options and Parts / Introduction of Special Features 1. Multi-stage gas booster for H2S-CO2 – Application of a gas booster capable of pressurizing gas supplied at low pressure (below 5bar) up to 100bar. 2. DAQ System Setup – Establishment of a real-time experimental condition monitoring and smooth data storage system using a PC. 3. Manufactured with a C-Clamp for easy opening and closing ? Designed with a C-Clamp instead of conventional bolts to enhance ease of opening. |

|

| Future Impact of the Product This device is a facility used for reliability testing of steel pipes employed in oil and gas drilling and transportation in the Middle East and the Caspian Sea, enabling testing according to the detailed experimental standards of the American Petroleum Institute. This enables the issuance of reliability and test certificates for oil and gas steel pipes, providing a competitive advantage in domestic steel pipe manufacturing technology and overseas exports. |

|

| Personnel Interview Considering the harsh conditions under which the experiments are conducted, the focus was on ensuring the safety and stable use of the equipment, and it is thought that this product can contribute to the improvement of domestic manufacturers’ technological capabilities. |

| Installed Products | Reactor stirrer reactor 500ml |

|---|---|

| Application Fields | Experimental |

| Delivery Date | 2018 |

| Installed Products | Nano disperser NH4-4000_Exd |

|---|---|

| Delivery Date | 2019 |

| Installed Products | Nano disperser NH4-4000_Exd |

|---|---|

| Delivery Date | 2019 |

| Installed Products | Nano disperser NH500s (40,000psi) |

|---|---|

| Delivery Date | 2019 |

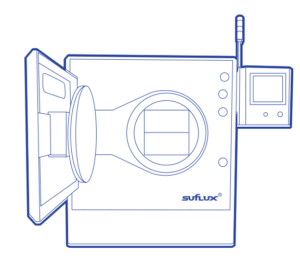

| Installed Products | Pressure Curing Oven (FA620_100_150H) |

|---|---|

| Delivery Date | 2019 |

| Installed Products | Pressure Curing Oven (FA300 series) |

|---|---|

| Delivery Date | 2019 |

| Installed Products | Pressure Curing Oven (FA620 series) |

|---|---|

| Application Fields | Semiconductors & Electronics, Display |

| Delivery Date | 2018 |

| Installed Products | Warm Isostatic Press TPP Press 2SET |

|---|---|

| Delivery Date | 2020. 02 |

| Contents | Summary Presses use pressure, distinguishing between an Isostatic Press that uses hydrostatic pressure to create uniform pressure conditions and a Hydraulic Press that applies pressure in one direction. Equipment using high pressure designed according to safety standards, manufacturing of reaction vessels, and pressure safety devices to ensure safety, providing a variety of models based on customer convenience and cost-effectiveness. |

| Installed Products | Cold Isostatic Press |

|---|---|

| Application Fields | Experimental |

| Delivery Date | 2019. 08 |

| Installed Products | Warm Isostatic Press (ISA-WIP-50-200) |

|---|---|

| Application Fields | Semiconductors & Electronics, MLCC |

| Delivery Date | 2019. 05 |

| Installed Products | Pressure Vessels 3L (PED Certification) |

|---|---|

| Application Fields | Experimental |

| Delivery Date | 2018. 11 |

| Installed Products | Pressure vessel bolt closure type (3L) |

|---|---|

| Application Fields | Experimental |

| Delivery Date | 2018. 05 |

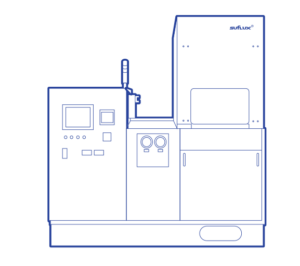

| Installed Products | Supercritical debinding equipment used in the injection molding process |

|---|---|

| Delivery Date | 2011. 06 |

| Contents | Summary Wax or Binder Removal Process |

| PROCESS – Removal Condition: 380kg/㎠ at 80℃ – Total Output: 12 ton/Day – Production Time: 3hr/Day X 2set |

|

| FEATURE – Continuous process-capable supercritical debinding equipment – Full system automation of plant equipment – High-pressure gas safety regulations approval and specialized construction – Inspection passed by Korea Gas Safety Corporation |

| Installed Products | Supercritical CO2 Dry System – Various Extraction Production |

|---|---|

| Delivery Date | 2009. 10 |

| Contents | Summary Supercritical extraction equipment capable of processing various bio samples |

| PROCESS Various Extraction Production (Various extraction productions) – Removal Condition: 700kg/㎠ at 90℃ – Total Output: 1 ton/Day – Production Time: 8hr/Day X 2set |

|

| FEATURE – Equipment capable of handling both solid and liquid samples – Post-process C.I.P treatment / Wide structure of the entire system – Full system automation of plant equipment – High-pressure gas safety regulations approval and specialized construction – Inspection passed by Korea Gas Safety Corporation |

| Installed Products | Supercritical CO2 extraction system |

|---|---|

| Delivery Date | 2008. 09 |

| Contents | Summary Pemicious ingredients removal process (Harmful Component Removal Process) Compliance with cGMP regulations(Current Good Manufacturing Practice) |

| PROCESS – Removal Condition: 450kg/㎠ at 80℃ – Total Output: 2.4 ton/day – Production Time: 6hr/batch x 2set |

|

| FEATURE – Equipment capable of handling both solid and liquid samples – Full system automation of plant equipment – High-pressure gas safety regulations approval and specialized construction – Inspection passed by Korea Gas Safety Corporation |

| Installed Products | Supercritical sesame oil extraction equipment Supercritical CO2 extraction system |

|---|---|

| Delivery Date | 2006. 06 |

| Contents | Summary Sesame oil extraction (Sesame oil extraction production) |

| PROCESS – Extraction Condition: 400㎏/㎠ at 80℃ – Total Output: 30 ton/day – Production Time : 20hr/day x 3set |

|

| FEATURE – Powder sample (sesame types) dedicated extraction equipment – Full system automation of plant equipment – High-pressure gas safety regulations approval and specialized construction – Inspection passed by Korea Gas Safety Corporation |

| Installed Products | Hydrothermal Synthesis synthetic resins System |

|---|---|

| Delivery Date | 2015. 01 |

| Contents | Summary Hydrothermal Synthesis synthetic resins System (Synthetic Resin Manufacturing Equipment) |

| PROCESS – Synthesis Condition: 100kg/㎠ at 260℃ – Total Output: 140kg/day – Production Time: 4hr/day x 2set |

|

| FEATURE – Equipment for manufacturing synthetic resins through hydrothermal synthesis reactions – Reaction equipment manufacturing through years of know-how – High-pressure gas safety regulations approval and construction companies – Inspection passed by Korea Occupational Safety&Health Agency |

| Installed Products | Large industrial pressure vessel (steam storage) |

|---|---|

| Delivery Date | 2012. 10 |

| Contents | Summary Facility for generating and storing steam or gas for energy production |

| PROCESS – Steam Condition : 200kg/㎠ at 365℃ – Heating Capacity : 144kw – Steam Capacity : 5㎥ x 1set |

|

| FEATURE – Production facility for steam & gas generators and storage – Reaction equipment manufacturing through years of know-how – Full system automation of plant equipment – High-pressure gas safety regulations approval and construction companies – Inspection passed by Korea Gas Safety Corporation |

| Installed Products | Pressure vessel plant usable in large industrial spaces |

|---|---|

| Delivery Date | 2012 |

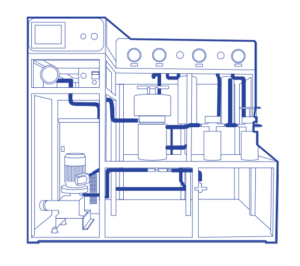

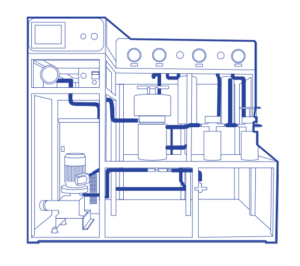

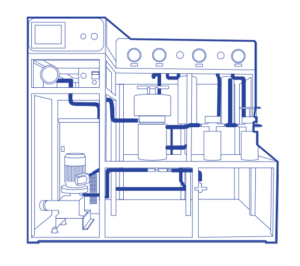

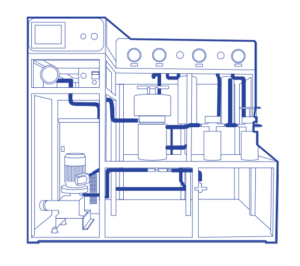

| Installed Products | Performance test facility for proving the integrity and reliability of Control Element Drive Mechanisms (CEDM) in pressurized water reactors |

|---|---|

| Delivery Date | 2008. 10 |

| Contents | Summary The power plant business designs and supplies production process equipment used in nuclear, thermal, and hydroelectric power generation processes. Our company has continuously evolved through designing and manufacturing power plants used in high-pressure vessel applications like steam and gas generation processes, meeting the domestic energy sector’s needs through extensive research and experimentation. This item is a performance test facility for proving the integrity and reliability of Control Element Drive Mechanisms (CEDM) in pressurized water reactors, delivered to Doosan Heavy Industries in October 2018. |

| PROCESS – Working Condition: 160kg/㎠ at 345℃ – Main Heating Capacity: 30kw x 2set – Circulation Pump: 15LPM, 3-PH, 5HP |

|

| FEATURE – Control Rod Drive Mechanism (CEDM) Reactor Operating Condition Performance Test Facility – Reactor manufacturing through years of know-how and various certifications – Full system automation of plant equipment – High-pressure gas safety regulations approval and specialized construction – Inspection passed by Korea Gas Safety Corporation |